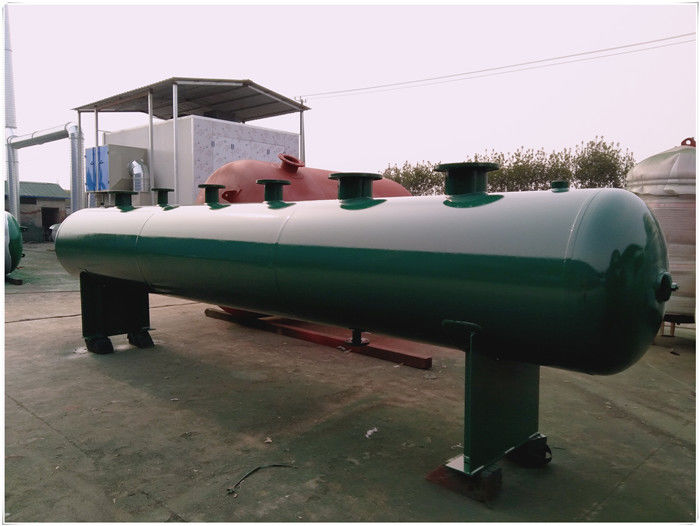

High Pressure Mechanical Active SA516-70 Carbon Steel Vertical Separator Vessel for

Water Treatment Plant

1. Company Profile

Shanghai Fengxian Equipment Vessel Factory was founded in 1982, and specializes in designing and manufacturing all kinds of pressure vessels. We have a high profile in the industry. And in 1998, we registered the brand of “Shen Jiang”. Our pressure vessels are widely used in petroleum, chemical, electronic, automotive, power generation, mining, pharmaceutical and other industries. Look forward to the cooperation with you in the increasingly powerful of our company.

2. Compressed air receiver tank Introduction:

1. Types: storage tank, air storage tank, liquid storage tank, vertical storage tank, horizontal storage tank, spherical tank, carbon steel storage tank,low-alloy steel storage tank, stainless steel storage tank and so on.

2. Materials: carbon steel, low-alloy steel, stainless steel and non-ferrous metals:

3. Pressure: low-pressure, medium-pressure and high-pressure.

4. Temperature: low-temperature , medium-temperature and high-temperature.

5. Medium: not only non-flammable,non-toxic and non-corrosive medium ,Water, air, oxygen, argon, helium, nitrogen

6. Processing capacity:maximum diameter:6m; maximum length:60m;maximum weight:600tons

7. Applicable Industries: petrochemical, coal chemical, precision chemical, nuclear power, metallurgical, pharmaceutical, machinery, food, pesticide, rubber, aerospace, and so on.

3. The important of compressed air receiver tank in air compressor system ?

Air buffer storage tank is an integral and important part of any compressed air system. Typically a receiver tank is sized at 6-10 times the flow rate of the system. So, if a compressor has a rating of 25 cfm at 100 psi, the receiver tank should be 150 cubic feet, minimum. In a compressed air system, a receiver tank provides the following benefits:

- The receiver tank acts as a reservoir of compressed air for peak demands.

- The receiver tank will help remove water from the system by allowing the air a chance to cool.

- The receiver tank minimizes pulsation in the system caused by a reciprocating compressor or a cyclic process downstream.

Much like a water reservoir provides water during times of drought and stores water during the wet times, an air receiver tank compensates for peak demand and helps balance the supply of the compressor with the demand of the system.

Receiver tanks are required by law to have a pressure relief valve and a pressure gauge. The relief valve should be set to 10% higher than the working pressure of the system.

It is also important to install either a manual or automatic drain on the receiver tank to remove water from the system.

4. Product Specifications

| Model NO. |

1.0/4.0 |

| Working pressure |

0.3m3~20M3 |

| Operating temperature |

100 °C |

| Vessel diameter |

customized |

| Total height of the container |

customized |

| Inlet diameter |

80mm |

| Outlet diameter |

80mm |

| Safety valve connection |

Rc1" |

5. Product advantages

| 1. Design |

Free design according customer's requirement |

| 2. Finished |

With in house Blast Cleaning and Paint Spray facilities, Internal and External finishes to specific BS/EN/ISO standards are common practice. Galvanization, Epoxy Resin, DWI approved paint, and other finishes at your request. |

| 3. Testing |

Materials, Processes, and Final Products are tested in a variety of ways, including: X-Ray, Tensile Tests, Hardness Tests, Dye Penetration, Hydrostatic, Radiographic etc. |

| 4. Document |

Full Certification can be supplied: – Certificates of Conformity, Hydraulic tests, weld procedures, weld tests, material certificates, pressure gauges, relief valves etc. upon your request. |

6. Our Advantages

1. 30 years manufacturing experience for high quality

2. A strong R & D team, 70 senior engineers can quickly offer drawing according to your requirements.

3.18 years famous brand, the world famous enterprises are looking for our air storage tank

4. AMSE, CE certificate has been adopted

5. 100 % quality inspection before shipping .more than 40 inspectors

6. Manufactured using high quality carbon steel.

7. Our customer :

BAOSTEEL, TOSHIBA, CONCH, SPC, DAS AUTO, CHINA SHENHUA, HONGTA GROUP, FOXCONN,

BMW, CSIC, WALT DISNEY, BOSCH, ANSTEEL, SINOMA, etc.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!